CLP Labels Explained

CLP Labels Explained

CLP labels play a critical role in communication chemical hazards clearly and consistently across the supply chain. For companies operating in oil and gas or other chemical intensive industries, understanding CLP requirements is essential for maintaining safety and regulatory compliance.

What Are CLP Labels?

CLP labels are the hazard communication labels required under the EU Classification, Labelling and Packaging Regulation. The CLP Regulation aligns the European Union with the UN Globally Harmonized System (GHS) for classifying and communicating chemical hazards. Its goal is to ensure that workers and consumers receive clear, consistent information about chemical risks regardless of where a product is manufactured or used within the EU.

Although CLP is an EU specific regulation, its underlying principles follow GHS. This means that companies operating in other regions often encounter similar requirements. Understanding CLP labels therefore helps organisations maintain consistent safety standards across global operations.

CLP Label Key Components

CLP sets detailed requirements for how label information must be presented to ensure safe handling and use. According to ECHA, a complete CLP label must include:

- Supplier information: The name, address and telephone number of the supplier. From 1 July 2026, this must be an EU based or EU established supplier.

- Nominal quantity: The amount of substance or mixture in packages supplied to the general public, unless already specified elsewhere on the packaging.

- Product identifiers: Clear identification of the substance or mixture so that users know exactly what it contains.

- Hazard information: Where applicable, this includes hazard pictograms, signal words, hazard statements, precautionary statements and any supplemental information required under other legislation.

CLP also defines how labels must be sized, formatted and positioned on packaging. Labels must be firmly attached to one or more surfaces of the packaging and remain visible, legible and durable throughout the life cycle of the product.

There are limited exemptions for certain packaging types, such as very small containers (typically less than 125 ml) or packaging that cannot reasonably accommodate full label content. In these cases, some hazard or precautionary statements, or pictograms, may be omitted.

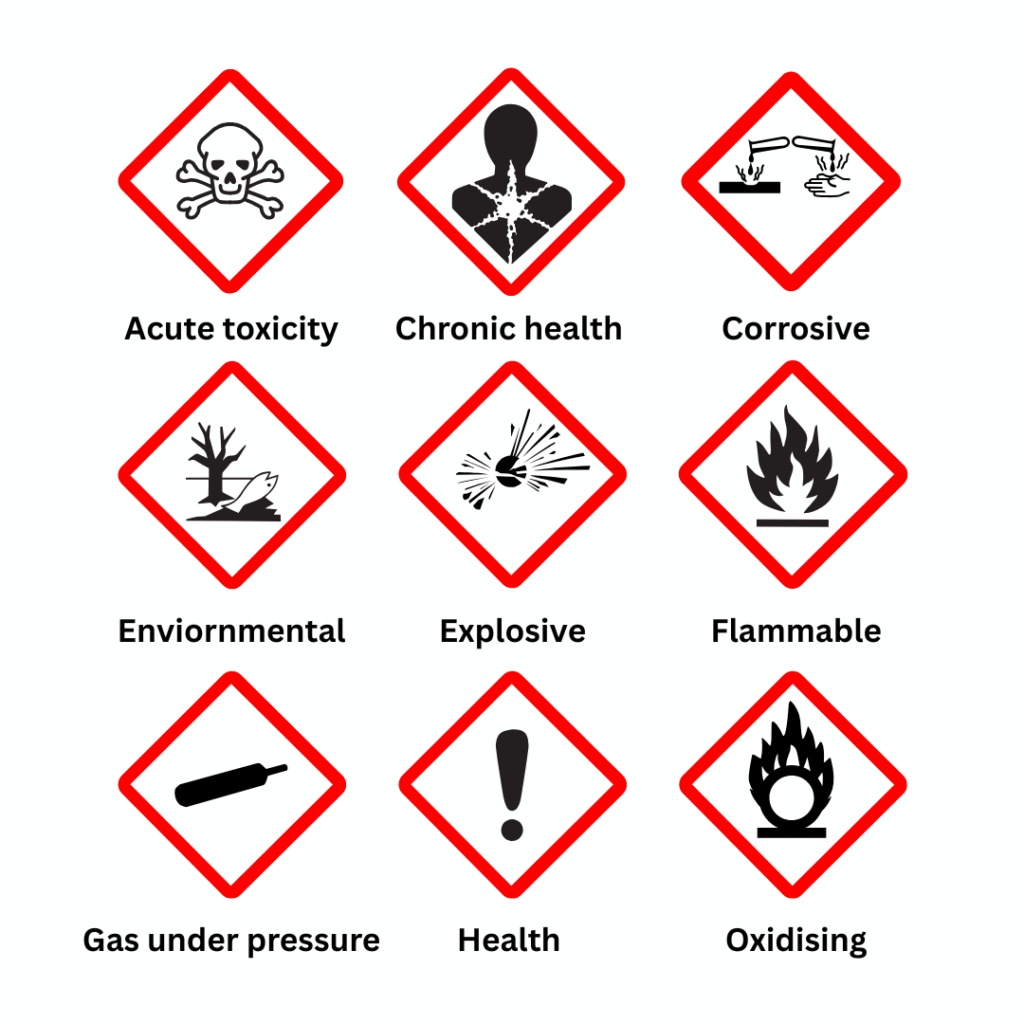

The Role of Hazard Pictograms

Hazard pictograms, sometimes referred to as chemical hazard symbols, provide quick visual warnings of the risks associated with a product. Under CLP, nine pictograms may be required depending on the classification of the substance or mixture. These include symbols for flammable materials, oxidisers, corrosive chemicals, acute toxicity, gas under pressure, environmental hazards and more.

Pictograms help workers interpret hazards immediately, which is particularly important in high-risk sectors such as oil and gas. Companies must use the correct pictograms based on the most severe hazards present and ensure that they appear clearly and at the required size.

Read more about hazard pictograms here.

CLP Labels Globally

How CLP Labels Affect International Companies

Chemical regulations differ across regions, but most countries now base their rules on the UN GHS model. This creates a degree of consistency, yet differences remain:

- Europe beyond the EU: Countries like Norway, Switzerland and the UK maintain frameworks largely aligned with CLP. Following Brexit, GB CLP applies in Great Britain with some divergence from EU CLP.

- United States: OSHA HazCom requires GHS aligned labels but uses some different phrasing and classification criteria.

- Canada: WHMIS 2015 aligns closely with GHS but still has distinct Canadian requirements.

- Middle East: Countries such as Saudi Arabia, UAE, Qatar and Oman have adopted GHS with local variations in implementation and enforcement.

- Asia Pacific: India and other countries follow GHS with region specific adaptations.

Common Compliance Challenges

Companies often face similar problems when managing CLP labels:

- Keeping hazard classifications updated as regulations change

- Maintaining accurate, multilingual label content for multiple regions

- Ensuring consistency between safety data sheet (SDS) data and label information

- Handling small packaging where space limitations complicate full label content

- Reducing manual errors that can lead to non-compliance or safety incidents

- Coordinating label updates across distributed teams and international sites

How ChemCenter Supports CLP Labelling

ChemCenter is a comprehensive digital solution that simplifies CLP labelling for international companies and solves several compliance challenges.

Centralised Chemical Data

ChemCenter consolidates all chemical information in one secure system. Classifications, hazard data and SDS content are interpreted automatically with digital tools, ensuring that every label is generated from accurate and consistent information. This significantly reduces the risk of manual errors and duplicated data handling.

Global SDS Database

ChemCenter includes access to a global database containing more than 13 million data sheets, giving users a broad foundation of verified chemical information. Companies can also upload their own SDS.

Efficient Labelling Workflows

From creation to printing and revision control, ChemCenter streamlines every step of the labelling process. Automated workflows help ensure that updates are applied consistently, and that obsolete labels are phased out. This allows organisations to respond quickly to regulatory changes and maintain compliance across multiple facilities.

Reduced Compliance Risk

By aligning label data with updated classifications and regulatory changes in real time, ChemCenter helps companies avoid costly non-compliance, product recalls and safety incidents. The platform supports internal oversight and ensures that label content always reflects the latest regulatory standards.

As global chemical regulations continue to evolve, accurate and compliant CLP labelling is essential for safe operations and maintaining market access. Companies must manage complex requirements, regional variations and constantly changing hazard data, often across multiple sites and countries. ChemCenter provides a reliable solution that simplifies these challenges by centralising data, streamlining workflows and supporting consistent, up to date labelling worldwide.